World's Highest-Efficiency Hydrogen System Scales Up for Mass Production

Hysata promises the world's cheapest hydrogen, thanks to a remarkable device that splits water into H2 and O2 at 95% efficiency – some 20% higher than the best conventional electrolyzers. The company has raised US$111 million to scale up production.

Hysata promises the world's cheapest hydrogen, thanks to a remarkable device that splits water into H2 and O2 at 95% efficiency – some 20% higher than the best conventional electrolyzers. The company has raised US$111 million to scale up production.

You have to throw some energy away to make hydrogen – typically around 20-30%, even with the best systems, which use around 52.5 kWh of energy to create a kilogram of hydrogen that can store 39.4 kWh of energy. It's a waste of renewable energy, and it contributes to the high cost of a green fuel option that's really struggling to compete against fossils and batteries in many applications.

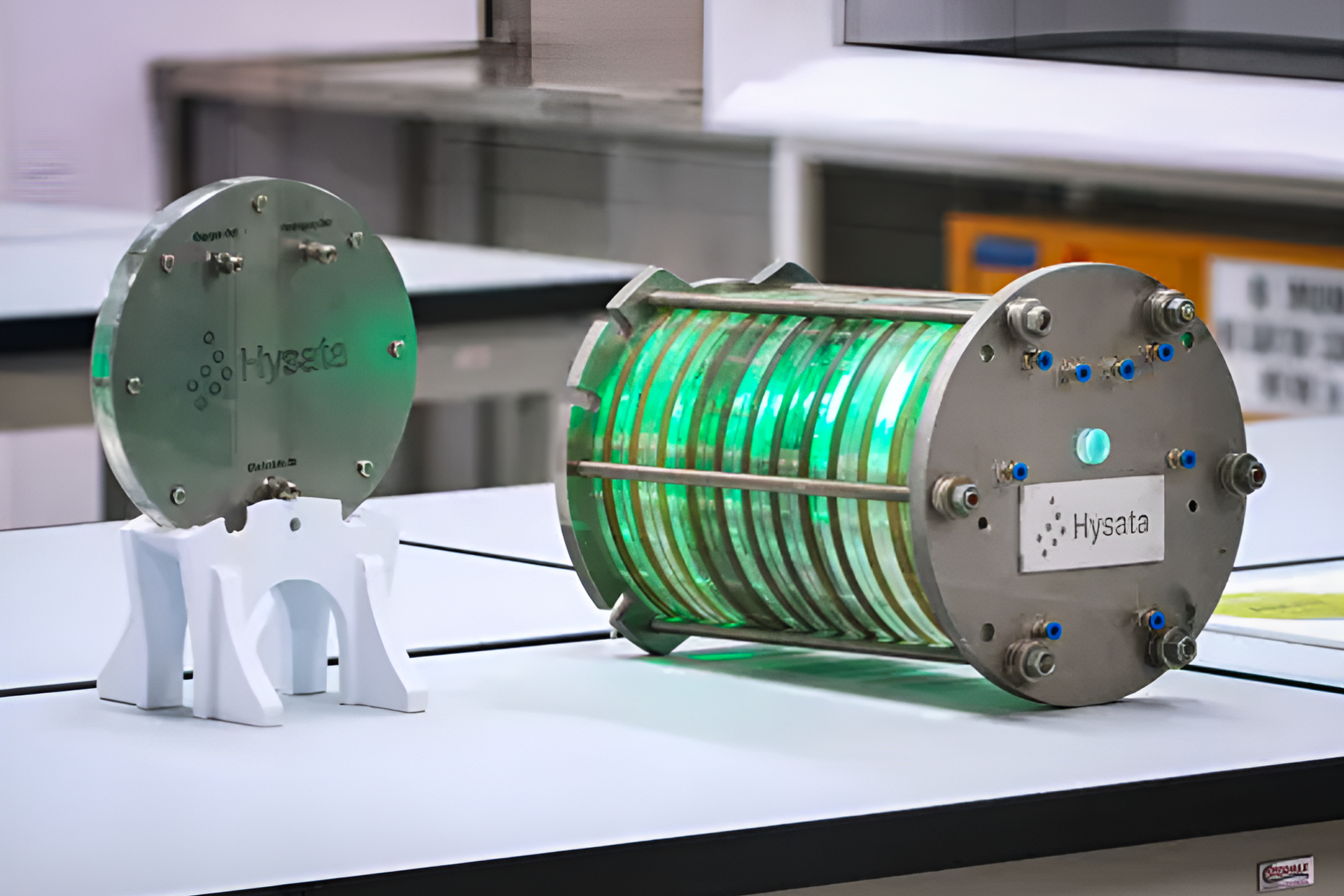

That's what makes Australian company Hysata's capillary-fed electrolyzer such an interesting device; at 95% efficiency, it uses just 41.5 kWh of energy to create that kilogram of hydrogen, cutting down operational costs for hydrogen producers – while also cutting down on CAPEX by being cheaper to install and run, to boot. The result: the cheapest green hydrogen going around.

Hysata says the key goal of its design – originally invented by scientists at the University of Wollongong – is to eliminate bubbles of hydrogen and oxygen gases in the electrolyte fluid between the anode and cathode. Bubbles are non-conductive, and they can stick to the surface of electrodes, meaning that less of the electrode is exposed to the electrolyte. This adds resistance to the system, and explains much of the energy that's wasted.

Hysata's design keeps the electrolyte at the bottom of the device, and allows it to be drawn up through a porous, hydrophilic separator between the electrodes. Each electrode has full, direct contact with the electrolyte on the inner side, and a dry chamber on the outer side. So as the water comes up that tube and gets split, the gases have nothing to bubble through. The resistance is greatly reduced, and capillary action draws more water up the central separator without requiring any kind of pump, and the overall efficiency takes a huge leap.

Indeed, Hysata says it's measured the efficiency of this cell at up to 98% in lab conditions, in peer-reviewed research published in the journal Nature Communications. So that 95% efficiency might be a realistic real-world figure. This certainly looks impressive to us – and investors appear to agree. Last week, the company announced a US$111 million Series B investment round. In a press release, the company said it "will use the funding to expand production capacity at its iconic beachside manufacturing facility in Wollongong, New South Wales, and further develop its technology as it focuses on reaching gigawatt scale manufacturing."

It looks like good news on the surface, and a valuable step towards decarbonization. Hydrogen promises to be a useful clean fuel and energy storage medium in a zero-carbon economy, carrying more energy per weight than batteries can, and offering a potential solution for hard-to-decarbonize sectors like aviation, shipping, heavy machinery and long-haul trucking.

But Hystata – along with every other electrolyzer manufacturer – faces some tough market conditions in the short term. A report recently released by research firm BloombergNEF points out that the problem isn't supply, or cost, or efficiency in today's electrolyzer market; it's demand. Only one pure electrolyzer company managed to turn a profit last year; the rest logged losses up to US$1.4 billion dollars.

The reason, according to Hydrogen Insight, is mainly due to "slower-than-expected rollout of subsidies in the US and EU," which has caused many developers on the demand side to delay or cancel their orders. Global electrolyzer production capacity at the end of 2023 was already seven times greater than the amount expected to be delivered in 2024, and several manufacturers have announced substantial expansions that'll more than double this capacity by 2025 – and that's not to take into account new manufacturers, which are also "flooding the market."

This might be a temporary situation, and Hysata's unique cost/benefit equation could place it well to ship units even in a difficult market – but it's certainly a financial strain on those left high and dry, and a sign that all is not going exactly to plan with the "massive, game-changing green hydrogen incentives" announced by the USA in 2022 as part of the Inflation Reduction Act.

Either way, green hydrogen will be produced using renewable energy, and Hysata's technology will ensure that the minimum possible renewable energy is thrown away in the process. That's excellent news – even if it can't help with energy lost in compression, cryogenic cooling, transport, or conversion back into electrical power at the other end. Those are opportunities for others!

Image: Hysata claims its capillary-feed electrolyzer is the world's most efficient, using some 20% less energy to produce hydrogen while also being cheaper to install and maintain. Credit: Hysata

Source: Hysata