Embarking on the frontiers of innovation, ITER, the International Thermonuclear Experimental Reactor, heralds a new era with its superconducting magnets—a groundbreaking technological marvel designed to operate at an astonishingly low temperature of 4 K (-269 °C), just above absolute zero. ITER’s primary purpose is to explore and demonstrate the potential of nuclear fusion as a clean and sustainable energy source for the future. With the capacity to carry an immensely powerful electrical current, reaching up to 68 kA, these magnets are poised for rigorous testing within a specialized cryostat infrastructure. The question of how these first-of-a-kind components navigate such extreme conditions becomes a pivotal inquiry at the forefront of scientific exploration.

Embarking on the frontiers of innovation, ITER, the International Thermonuclear Experimental Reactor, heralds a new era with its superconducting magnets—a groundbreaking technological marvel designed to operate at an astonishingly low temperature of 4 K (-269 °C), just above absolute zero. ITER’s primary purpose is to explore and demonstrate the potential of nuclear fusion as a clean and sustainable energy source for the future. With the capacity to carry an immensely powerful electrical current, reaching up to 68 kA, these magnets are poised for rigorous testing within a specialized cryostat infrastructure. The question of how these first-of-a-kind components navigate such extreme conditions becomes a pivotal inquiry at the forefront of scientific exploration.

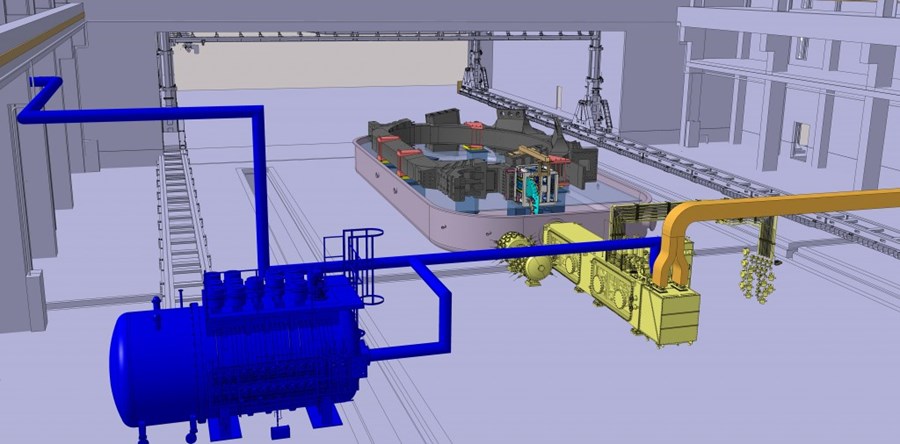

“Testing at 4 K and at 80 K are completely different operations,” explains David Grillot, ITER deputy program manager for plant systems and former leader of the Cryogenics Section. "Considering that a toroidal field coil’s mass is in excess of 300 tonnes, the colder test requires considerable infrastructure—a large cryostat, a dedicated power supply, an electrical feeder and associated instrumentation and an interface with a large refrigerator located inside the cryoplant. It’s not comparable at all to testing at 80 K, which is relatively simple and has been done routinely.”

While testing at 80 K provides insights into 90% of the thermal and mechanical constraints, it falls short of capturing the true electrical behavior of the coils. Superconductivity is only fully established at 4 K, necessitating a specialized and challenging testing approach.

“All six ITER ring-shaped poloidal field coils and 14 out of 19 D-shaped toroidal field coils will have been tested at the more clement temperature of 80 K before their installation in the ITER machine,” says Neil Mitchell, ITER’s historical magnet expert. However, testing at 4 K was only done for the US-procured central solenoid modules. “US ITER demanded that a full-current 4 K factory acceptance test be performed on each central solenoid module before shipment to ITER,” adds Mitchell. “It definitely made sense as a 4 K test can achieve conditions pretty close to a module's operating point in ITER.”

Proceeding to 4 K tests has long been discussed inside ITER, with experts and management confronting analyses and debating the pros and cons. Confidence in the manufacturing process and other considerations eventually led to the decision not to proceed.

“Although we are not starting from scratch – coils at JT60-SA and W7-X have been tested at 4 K – the size of the ITER coils and hence the dimensioning of the installation present considerable challenges,” says David Grillot. “Also, we need to finalize the facility in two years when it would normally take twice that time.”

The cold test facility’s design, located in the vacated part of the winding facility, faces significant technical and organizational challenges. The project team aims to set up the infrastructure in less than two years, with plans for testing at least one coil from each manufacturer (Mitsubishi and Toshiba in Japan; ASG-SIMIC in Europe).

The cryogenic distribution system is another critical aspect, ensuring the supply of cryogenic fluids to superconducting magnets, cryopumps and other components. The auxiliary cold boxes, positioned in the Tokamak Building, play a crucial role in distributing cooling fluids to various clients inside the ITER machine.

“Providing cryogenic fluids to the superconducting magnets, cryopumps, and other ‘clients’ in the ITER machine requires a sophisticated distribution system that ramifies to deliver the cryoplant-originating fluids to their final destinations,” as described in a recent ITER update.

The involvement of domestic agencies extends beyond component delivery. Alessandro Bonito-Oliva, Head of the Tokamak Program at ITER, emphasizes the collaborative effort in procuring superconducting toroidal field coils. The completion of this project marks a significant achievement, with Sandro now overseeing the integration of coils into the ITER machine.

“Relations between the ITER Organization and the domestic agencies are complex because within a shared objective, the approach can differ depending on whether you are reasoning as a supplier or as the machine owner,” says Sandro Bonito-Oliva. The ITER Organization’s reorganization aims to integrate diverse perspectives and talent from domestic agencies to optimize the entire process from design to operation.

It is important that a domestic agency’s involvement does not stop with the delivery of components. “When you've produced a technically complex component and accumulated all the technical know-how, you can make a real contribution onsite during integration and commissioning,” adds Bonito-Oliva. “My first months here have been an incredible source of motivation, which at this advanced stage of my career I thought would be impossible to find. I would strongly encourage others to follow in my steps!” www.iter.org

Image: The cold test facility will be located in the partially vacated poloidal field coil winding facility. Supercritical helium at 4 K will be delivered by way of a cryogenic auxiliary cold box (blue) interfacing with the cryoplant; electrical power will be fed by a busbar (orange) originating in a dedicated power supply system. Both cryogens and electrical power will be delivered to the magnet by way of a feeder (yellow). As the coil will be in the horizontal position, a new design is required for connecting it to the feeder. Credit: ITER