Ampo Poyam Valves (AMPO), with a history spanning nearly six decades, has established itself as a significant player in the realm of highly engineered valves and fluid handling solutions tailored for demanding applications and services. Drawing from its extensive experience, the company has earned a reputation for handling international projects with precise technical specifications, providing dependable solutions with minimal maintenance costs. Core principles at AMPO encompass effective supply chain management, including an integrated foundry and robust field support through its service division.

Ampo Poyam Valves (AMPO), with a history spanning nearly six decades, has established itself as a significant player in the realm of highly engineered valves and fluid handling solutions tailored for demanding applications and services. Drawing from its extensive experience, the company has earned a reputation for handling international projects with precise technical specifications, providing dependable solutions with minimal maintenance costs. Core principles at AMPO encompass effective supply chain management, including an integrated foundry and robust field support through its service division.

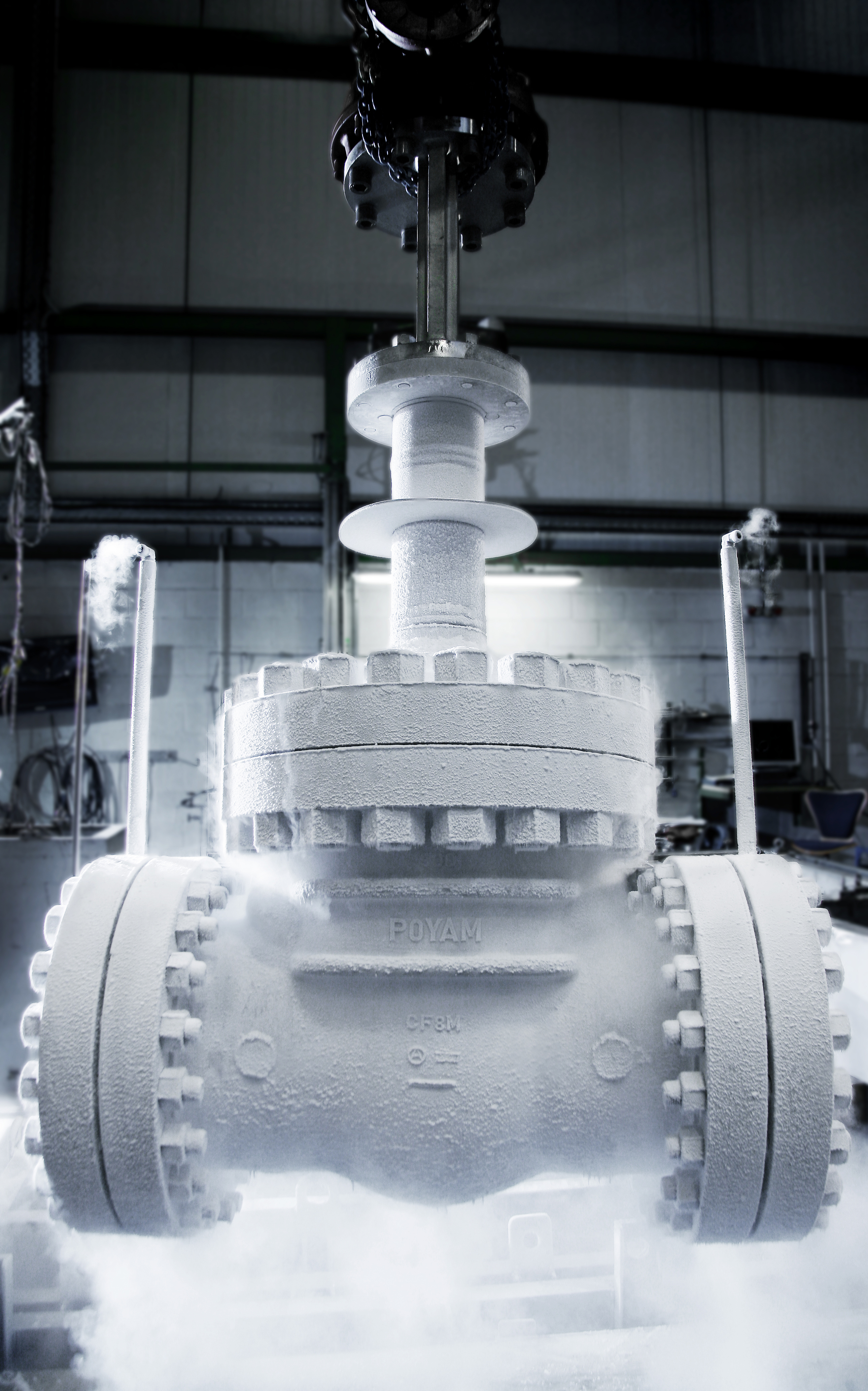

Established in 1964, the company has cultivated expertise in critical applications, including cryogenic temperatures, high temperatures, corrosive media and erosive and abrasive environments, both on the surface and underwater, always meeting rigorous conditions with unwavering reliability.

Cryo and Low Temp Expertise

A pivotal strength of the company lies in its proficiency in cryogenic applications and low temperature solutions. Millions of cryogenic valves have been installed at facilities operated by major energy contractors worldwide. These valves play a vital role in liquefied natural gas (LNG) and liquefied petroleum gas (LPG) terminals and transportation vessels. AMPO manufactures valves covering the entire LNG and LPG supply chain, from gas retrieval to transportation pipelines, liquefaction, carrier vessels and storage tanks. These valves are also suitable for low temperature applications such as ethylene, oxygen, nitrogen, petrochemical plants and refineries.

AMPO employs skilled engineers who employ modern design tools like 3D CAD and FEM analysis, advanced multibody and fluid-structure interaction modeling, and rigorous quality assurance practices throughout the development, fabrication and qualification processes. With more than 60 years of experience in manufacturing cryogenic valves, AMPO is recognized as a leading manufacturer of highly engineered valves for the LNG market, including various types of cryogenic valves.

Applications

Applications

AMPO excels in virtual prototyping, design and manufacturing of critical cryogenic valves across the temperature spectrum, suitable for LNG or liquefied air gases, as well as liquefied hydrogen or helium. The valve portfolio includes microflow control and shut-off valves, axial check valves and top-load ball valves. Testing is pivotal for quality validation, covering valve sizes from DN2 to DN2500. The company's testing facilities encompass hydrostatic and gas pressure test benches, LN2 baths and clean rooms for cryogenic and oxygen service valve assembly. Mass spectrometers are employed for helium leak detection.

Cryogenic helium leak and pressure tests at 77 K are standard procedures, essential for valves operating in extreme conditions above 80 K. Tailor-made solutions are integral to AMPO's engineering activities, with a focus on delivering integrated smart solutions as turnkey projects. AMPO’s testing technician staff holds certification for leak testing level 2 using the trace gas method per ISO 9712. Test procedures adhere to International Standard ISO 27895 for leak testing of vacuum valves, commonly used for gas flow or vacuum pressure control. Key parameters for verification include:

• Sniffing leak detection ≤ 5x10^-10 Pa·m^3/s

• Vacuum leak detection ≤ 5x10^-13 Pa·m^3/s

These capabilities and extensive facilities empower AMPO to validate product quality, assess valve performance under various conditions and develop highly engineered solutions. The company is positioned to provide clients with reliable valve solutions tailored to project requirements.

Recent Developments

AMPO has recently introduced liquid hydrogen and helium on/off and control valves with flexible designs. Additionally, the company has expanded its capabilities in integrated smart controls, enhancing its position in instrumentation and system solutions.

AMPO remains committed to its core principles of excellence, innovation and reliability. The company continuously invests in research and development to stay at the forefront of valve technology. Its commitment to excellence is reflected in a diverse portfolio of valves designed to handle a wide range of challenging applications. AMPO looks forward to its future as a global industry leader, backed by experience and focused on innovation. www.ampo.com

Images: Cryogenic valve testing. Credit: AMPO; Cryogenic top entry ball valve. Credit: AMPO