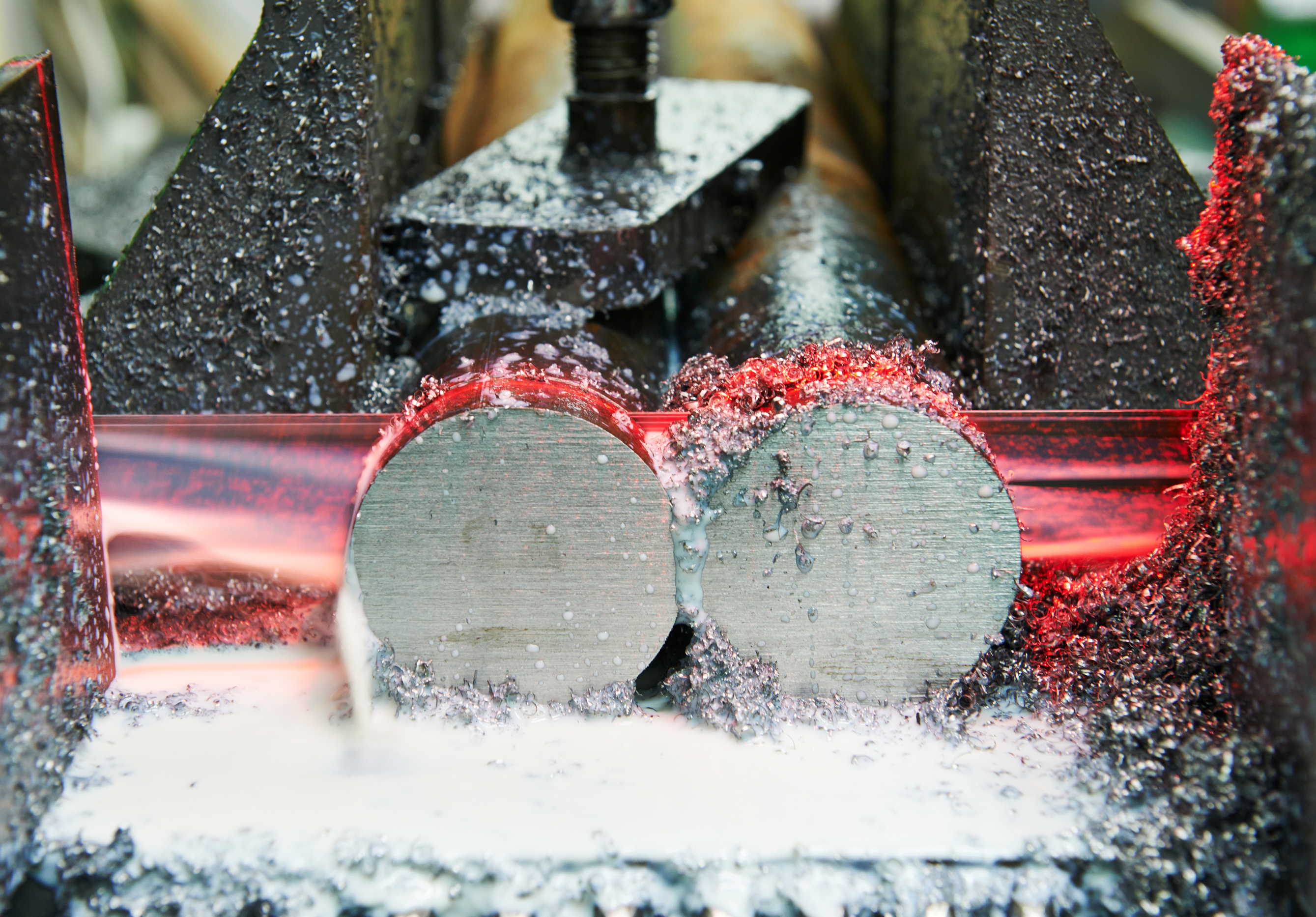

Ever since the Stone Age, people have searched for the most effective ways to cut and shape materials for best use. This quest has most recently resulted in revolutionary breakthroughs and developments like lasers, plasma beams, and water jets as cutting instruments. Despite these advances, the overwhelming majority of cutting tasks still require metal with a sharpened edge, which has one key undesirable trait: it wears out and gets dull. Not so with CryoEdge, a sales and service company based in the Spokane, Washington area. CryoEdge’s essential issue goes back to prehistoric times: how can we cut things better and make the tools we use for cutting last longer?

Ever since the Stone Age, people have searched for the most effective ways to cut and shape materials for best use. This quest has most recently resulted in revolutionary breakthroughs and developments like lasers, plasma beams, and water jets as cutting instruments. Despite these advances, the overwhelming majority of cutting tasks still require metal with a sharpened edge, which has one key undesirable trait: it wears out and gets dull. Not so with CryoEdge, a sales and service company based in the Spokane, Washington area. CryoEdge’s essential issue goes back to prehistoric times: how can we cut things better and make the tools we use for cutting last longer?

How to Avoid a Tank Collapse

The industrial gas industry produces the elemental components of “air” (nitrogen, oxygen, and argon) that are used in other industries as part of their processes. Once separated from air, each element exists as an extremely cold cryogenic temperature liquid. Typical liquid temperatures are −185° C. Large, field-erected tanks are used to store these liquids, and these tanks range from 100,000 gallons to over 2,000,000 gallons in size. API-620/Appendix Q standards, or their equivalent, are the routine guiding design documents. These tanks are built as flat-bottom, domed-top tanks, typically with stainless steel inner containers, carbon-steel outer containers, and the top/side insulation space between these tanks filled with three to five feet (radial dimension) of granular perlite insulation. The inner tank sits on a sandwich structure of Foamglas® insulation and concrete. During cooldown and commissioning, these tanks need to be dried, inerted, and brought down to very cold temperatures to allow product to be introduced. If done incorrectly during cooldown, these tanks risk vacuum collapse. This article discusses the details surrounding one such occurrence.

The industrial gas industry produces the elemental components of “air” (nitrogen, oxygen, and argon) that are used in other industries as part of their processes. Once separated from air, each element exists as an extremely cold cryogenic temperature liquid. Typical liquid temperatures are −185° C. Large, field-erected tanks are used to store these liquids, and these tanks range from 100,000 gallons to over 2,000,000 gallons in size. API-620/Appendix Q standards, or their equivalent, are the routine guiding design documents. These tanks are built as flat-bottom, domed-top tanks, typically with stainless steel inner containers, carbon-steel outer containers, and the top/side insulation space between these tanks filled with three to five feet (radial dimension) of granular perlite insulation. The inner tank sits on a sandwich structure of Foamglas® insulation and concrete. During cooldown and commissioning, these tanks need to be dried, inerted, and brought down to very cold temperatures to allow product to be introduced. If done incorrectly during cooldown, these tanks risk vacuum collapse. This article discusses the details surrounding one such occurrence.

Read More

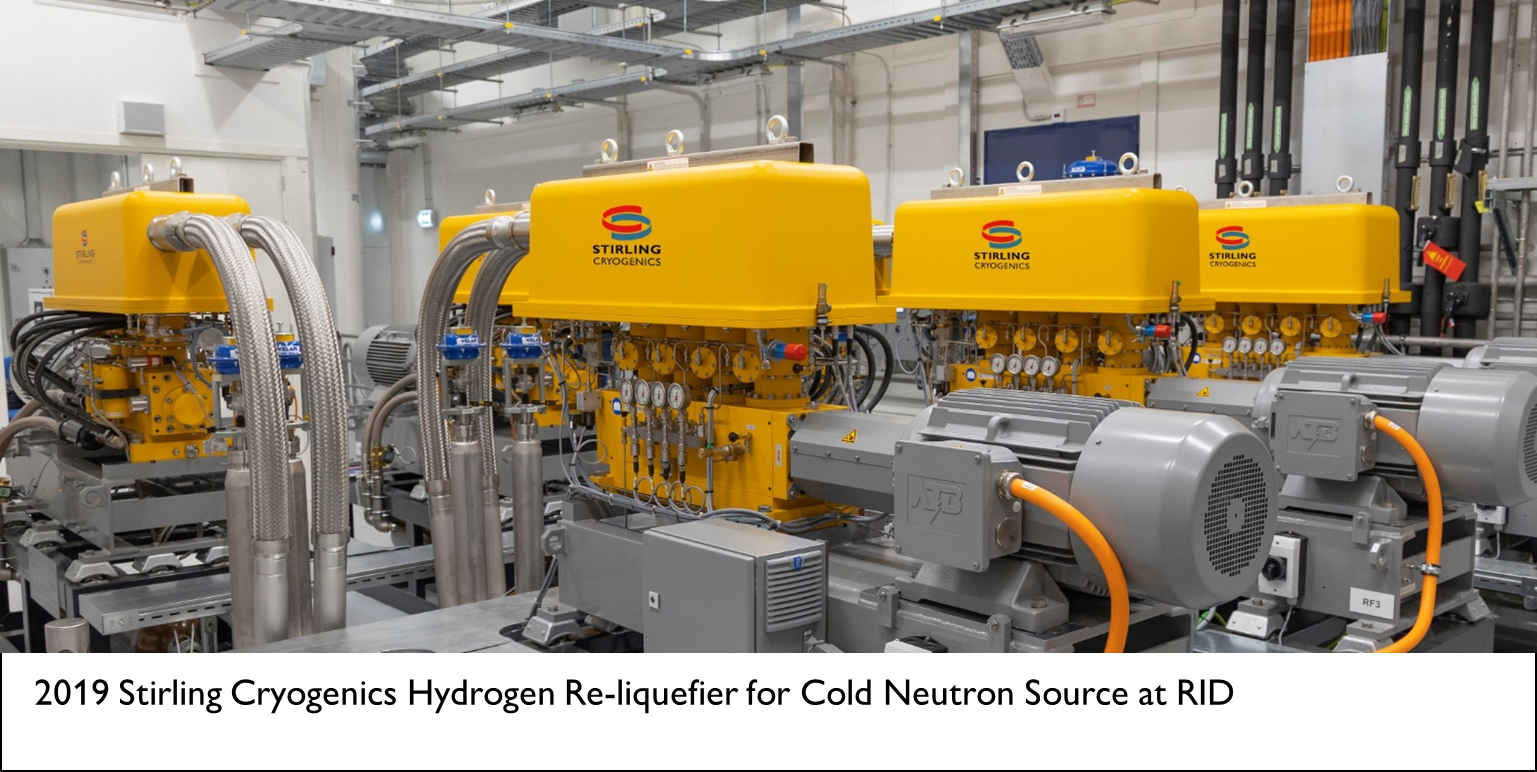

Stirling cryogenerators have been widely used since the 1960s and 1970s for the production of LH2 at various institutes and research laboratories all over the world. In materials sciences, small-scale production was used to study the properties and behavior of LH2 and its effect on materials.

Stirling cryogenerators have been widely used since the 1960s and 1970s for the production of LH2 at various institutes and research laboratories all over the world. In materials sciences, small-scale production was used to study the properties and behavior of LH2 and its effect on materials.

Read More

Dylan CHP LLC has researched, developed, and patented advanced steam generation technology, utilizing hydrogen to generate clean energy electricity. The Dylan System is based on extreme heat preservation (EHP), the heart of the Dylan patent that allows the Dylan Energy-Efficient System to achieve nameplate steam output while consuming only a small fraction of the hydrogen. Dylan’s flexible EHP technology can easily be retrofitted to burn other fuels including natural gas, LNG, flare gas, landfill gas, MSW, or other traditional fuels as feedstock that more conventional systems require. Dylan continues to engineer its system to maximize quality, energy efficiencies and reliability to its customers.

Dylan CHP LLC has researched, developed, and patented advanced steam generation technology, utilizing hydrogen to generate clean energy electricity. The Dylan System is based on extreme heat preservation (EHP), the heart of the Dylan patent that allows the Dylan Energy-Efficient System to achieve nameplate steam output while consuming only a small fraction of the hydrogen. Dylan’s flexible EHP technology can easily be retrofitted to burn other fuels including natural gas, LNG, flare gas, landfill gas, MSW, or other traditional fuels as feedstock that more conventional systems require. Dylan continues to engineer its system to maximize quality, energy efficiencies and reliability to its customers.

Read More

Engineering and medical researchers at the University of Minnesota Twin Cities and Mayo Clinic have developed a new process for successfully storing specialized pancreatic islet cells at very low temperatures and rewarming them with a laser and gold nanoparticles, enabling the potential for on-demand islet transplantation. The breakthrough discovery in cryopreservation is a major step forward in a cure for diabetes.

Engineering and medical researchers at the University of Minnesota Twin Cities and Mayo Clinic have developed a new process for successfully storing specialized pancreatic islet cells at very low temperatures and rewarming them with a laser and gold nanoparticles, enabling the potential for on-demand islet transplantation. The breakthrough discovery in cryopreservation is a major step forward in a cure for diabetes.

Read More

Due to limitations in size and power dissipation, many prevalent measurement methods are incompatible with low temperature applications. Hall effect sensors have emerged as the superior option because of their compact size and low-power requirement. Until now, conventional Hall sensors have themselves been limited by material capabilities and the quantum Hall effect (QHE). Paragraf®’s Cryogenic Graphene Hall Sensors (GHS-C), however, enhance the ability of companies that make and/or use superconducting magnets to conduct continuous measurements in low temperature and high-field environments. This means ending the reliance on factory calibration or current-to-field measurements to evaluate these systems. With its patented graphene deposition process, Paragraf averts limitations by producing the GHS-C, which achieves operation in temperatures down to mK and field measurements of over 30 T.

Due to limitations in size and power dissipation, many prevalent measurement methods are incompatible with low temperature applications. Hall effect sensors have emerged as the superior option because of their compact size and low-power requirement. Until now, conventional Hall sensors have themselves been limited by material capabilities and the quantum Hall effect (QHE). Paragraf®’s Cryogenic Graphene Hall Sensors (GHS-C), however, enhance the ability of companies that make and/or use superconducting magnets to conduct continuous measurements in low temperature and high-field environments. This means ending the reliance on factory calibration or current-to-field measurements to evaluate these systems. With its patented graphene deposition process, Paragraf averts limitations by producing the GHS-C, which achieves operation in temperatures down to mK and field measurements of over 30 T.

Read More

Following a successful launch of NASA’s Space Launch System (SLS), the most powerful rocket in the world, the agency’s Orion spacecraft is on its way to the Moon as part of the Artemis program. Carrying an uncrewed Orion, SLS lifted off for its flight test debut at 1:47 a.m. EST Wednesday, November 16, 2022, from Launch Pad 39B at NASA’s Kennedy Space Center in Florida.

Following a successful launch of NASA’s Space Launch System (SLS), the most powerful rocket in the world, the agency’s Orion spacecraft is on its way to the Moon as part of the Artemis program. Carrying an uncrewed Orion, SLS lifted off for its flight test debut at 1:47 a.m. EST Wednesday, November 16, 2022, from Launch Pad 39B at NASA’s Kennedy Space Center in Florida.

Read More

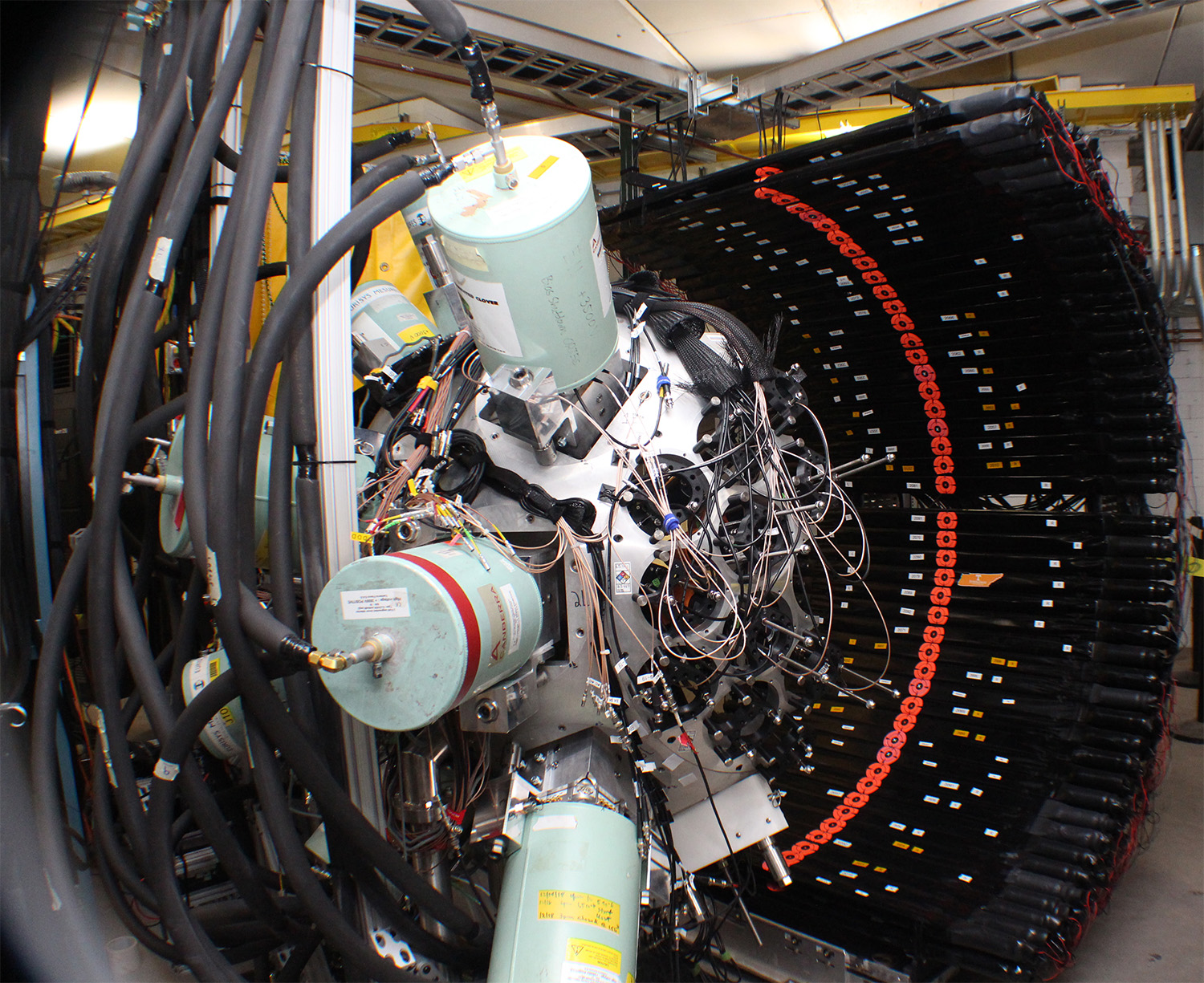

A new study led by the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) has measured how long it takes for several kinds of exotic nuclei to decay. The paper, published today in Physical Review Letters, marks the first experimental result from the Facility for Rare Isotope Beams (FRIB), a DOE Office of Science user facility operated by Michigan State University.

A new study led by the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) has measured how long it takes for several kinds of exotic nuclei to decay. The paper, published today in Physical Review Letters, marks the first experimental result from the Facility for Rare Isotope Beams (FRIB), a DOE Office of Science user facility operated by Michigan State University.

Read More

How does something that looks like a stack of orange inner tubes covered in a black tarp survive temperatures reaching 3,000 degrees Fahrenheit as it plunges through the atmosphere? An upcoming technology demonstration uses advanced materials to make a heat shield that's tougher than it looks.

How does something that looks like a stack of orange inner tubes covered in a black tarp survive temperatures reaching 3,000 degrees Fahrenheit as it plunges through the atmosphere? An upcoming technology demonstration uses advanced materials to make a heat shield that's tougher than it looks.

Read More

VEIR, an early-stage technology company based in Woburn, Mass., is pioneering the first application of superconducting transmission over long distances, a key component to deliver renewable sources of energy safely and reliably from where it is generated to where it is needed, often cross-country. VEIR is teaming up with National Grid, an electricity, natural gas, and clean energy delivery company with operations in the US and UK, that will aid the project in product development with the joint goal of demonstrating the new technology on a protected area of the grid.

VEIR, an early-stage technology company based in Woburn, Mass., is pioneering the first application of superconducting transmission over long distances, a key component to deliver renewable sources of energy safely and reliably from where it is generated to where it is needed, often cross-country. VEIR is teaming up with National Grid, an electricity, natural gas, and clean energy delivery company with operations in the US and UK, that will aid the project in product development with the joint goal of demonstrating the new technology on a protected area of the grid.

Read More

For astronauts, staying cool and comfortable on China's Tiangong space station is no problem. The station orbits Earth in about 90 minutes at an altitude of 400 km. It experiences large fluctuations in temperature, ranging from 150 degrees Celsius when the station is exposed to the sun to minus 100 degrees Celsius when over the night side of the planet. So how to protect station residents from extreme heat and cold during their six-month stay in orbit? The answer lies in several thermal control designs courtesy of the China Academy of Space Technology.

For astronauts, staying cool and comfortable on China's Tiangong space station is no problem. The station orbits Earth in about 90 minutes at an altitude of 400 km. It experiences large fluctuations in temperature, ranging from 150 degrees Celsius when the station is exposed to the sun to minus 100 degrees Celsius when over the night side of the planet. So how to protect station residents from extreme heat and cold during their six-month stay in orbit? The answer lies in several thermal control designs courtesy of the China Academy of Space Technology.

Read More

Three Questions: Emre Gençer on the role of blue hydrogen in decarbonizing the world’s energy systems

In the past several years, hydrogen energy has increasingly become a more central aspect of the clean energy transition. Hydrogen can produce clean, on-demand energy that could complement variable renewable energy sources such as wind and solar power. That being said, pathways for deploying hydrogen at scale have yet to be fully explored. In particular, the optimal form of hydrogen production remains in question.

In the past several years, hydrogen energy has increasingly become a more central aspect of the clean energy transition. Hydrogen can produce clean, on-demand energy that could complement variable renewable energy sources such as wind and solar power. That being said, pathways for deploying hydrogen at scale have yet to be fully explored. In particular, the optimal form of hydrogen production remains in question.

Read More

First Radio-Astronomy Cryogenic Receivers with All-Metal 3D-Printed RF Components

The NAOJ ALMA Project and Advanced Technology Center have successfully fabricated corrugated all-metal 3D-printed horns for the ALMA Band 1 receivers (Radio Frequency: 35-50 GHz). Since around 2015, the NAOJ ALMA Project and the Advanced Technology Center have been studying the applications of additive manufacturing (AM), which produces three-dimensional objects by depositing, joining, and solidifying materials based on 3D models input to a control computer. Since astronomical receivers often have only one or two devices of each type per instrument and they require unique custom-made components, there is potential for effective use of additive manufacturing.

The NAOJ ALMA Project and Advanced Technology Center have successfully fabricated corrugated all-metal 3D-printed horns for the ALMA Band 1 receivers (Radio Frequency: 35-50 GHz). Since around 2015, the NAOJ ALMA Project and the Advanced Technology Center have been studying the applications of additive manufacturing (AM), which produces three-dimensional objects by depositing, joining, and solidifying materials based on 3D models input to a control computer. Since astronomical receivers often have only one or two devices of each type per instrument and they require unique custom-made components, there is potential for effective use of additive manufacturing.

Read More

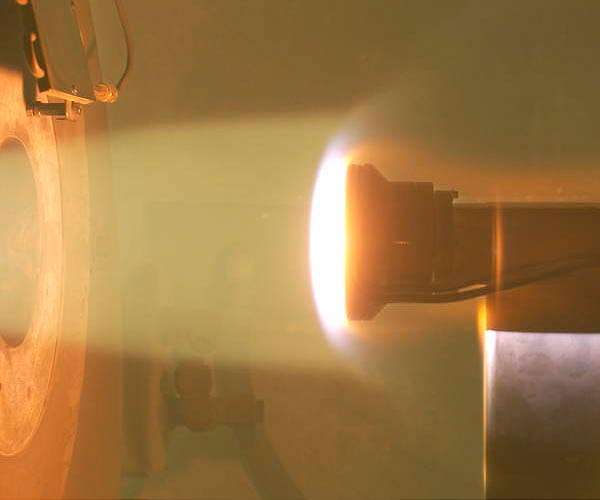

Explained: Why ISRO again test-fired its CE-20 Cryogenic Engine, ahead of next flight in 2023

The Indian Space Research Organization (ISRO) has successfully test-fired its CE-20 Cryogenic engine, as part of the preparation for the next launch of its heaviest rocket. This latest test comes a week after the Indian Space agency placed 36 satellites of the UK-based 'OneWeb', into Low Earth Orbit, using its heaviest rocket LVM3. The next launch to be carried out using the LVM3 will be performed sometime around January or February 2023, Chairman, ISRO, Dr. S. Somanath told WION.

The Indian Space Research Organization (ISRO) has successfully test-fired its CE-20 Cryogenic engine, as part of the preparation for the next launch of its heaviest rocket. This latest test comes a week after the Indian Space agency placed 36 satellites of the UK-based 'OneWeb', into Low Earth Orbit, using its heaviest rocket LVM3. The next launch to be carried out using the LVM3 will be performed sometime around January or February 2023, Chairman, ISRO, Dr. S. Somanath told WION.

Read More

Azenta Hosts First Cryogenic Considerations for Cell & Gene Therapy Symposium

Azenta Life Sciences, a leading provider of life sciences solutions worldwide, hosted the Cryogenic Considerations for Cell and Gene Therapy Symposium in Boston, MA October 17-19th. The symposium brought together over 100 participants across over 60 organizations including top cryobiology experts to discuss the nuances of cryogenic supply chain, transient warming, and thawing of advanced therapies—from collection of raw materials to manufacturing and distribution of cell and gene therapies.

Azenta Life Sciences, a leading provider of life sciences solutions worldwide, hosted the Cryogenic Considerations for Cell and Gene Therapy Symposium in Boston, MA October 17-19th. The symposium brought together over 100 participants across over 60 organizations including top cryobiology experts to discuss the nuances of cryogenic supply chain, transient warming, and thawing of advanced therapies—from collection of raw materials to manufacturing and distribution of cell and gene therapies.

Read More

Almac Clinical Services, a member of The Almac Group, announced a new state-of-the-art cryogenic service solution within its Durham, N. C. campus to support cell and gene therapies. This latest investment from Almac adds to the company’s overall $4 million investment to date in innovative cold chain technology in North Carolina. The Cryogenic Service Solution ensures an unbroken chain of custody from product line to patient, for sponsors of advanced therapy trials.

Almac Clinical Services, a member of The Almac Group, announced a new state-of-the-art cryogenic service solution within its Durham, N. C. campus to support cell and gene therapies. This latest investment from Almac adds to the company’s overall $4 million investment to date in innovative cold chain technology in North Carolina. The Cryogenic Service Solution ensures an unbroken chain of custody from product line to patient, for sponsors of advanced therapy trials.

Read More

Cryo-EM Reveals Cold-sensing Cell Channels Manipulated by Chemicals to Induce Cold Sensation

A team of researchers affiliated with the Duke University School of Medicine, Lehigh University and the National Institutes of Health has revealed the molecular means by which cold-sensing channels in cells are manipulated by certain chemicals to induce a cold sensation. The study is published in the journal Science.

A team of researchers affiliated with the Duke University School of Medicine, Lehigh University and the National Institutes of Health has revealed the molecular means by which cold-sensing channels in cells are manipulated by certain chemicals to induce a cold sensation. The study is published in the journal Science.

Read More

Air Liquide is advancing space exploration, having signed a contract with space propulsion expert Avio for the design of the new generation of cryogenic tanks for the upper stage of the future Vega-E launcher. The project is coordinated by the European Space Agency (ESA), and the launcher will use cryogenic tanks filled with a mixture of oxygen stored at -182° C and methane stored at -161° C to act as propellant for the oxygen-methane engine.

Air Liquide is advancing space exploration, having signed a contract with space propulsion expert Avio for the design of the new generation of cryogenic tanks for the upper stage of the future Vega-E launcher. The project is coordinated by the European Space Agency (ESA), and the launcher will use cryogenic tanks filled with a mixture of oxygen stored at -182° C and methane stored at -161° C to act as propellant for the oxygen-methane engine.

Read More

The extremely low temperatures required for performing state-of-the-art physics experiments and operating large quantum processors have been achieved in Project Goldeneye. IBM researchers have successfully demonstrated the proof-of-concept technology for a dilution refrigerator capable of cooling future generations of quantum experiments. You can watch a sneak peek of the IBM Quantum System Two here.

The extremely low temperatures required for performing state-of-the-art physics experiments and operating large quantum processors have been achieved in Project Goldeneye. IBM researchers have successfully demonstrated the proof-of-concept technology for a dilution refrigerator capable of cooling future generations of quantum experiments. You can watch a sneak peek of the IBM Quantum System Two here.

Read More

The crew members assigned to NASA’s SpaceX Crew-5 mission went into orbit following their launch to the International Space Station on Wednesday, October 5, from Launch Complex 39A at NASA’s Kennedy Space Center in Florida. The international crew will serve as the agency’s fifth commercial crew rotation mission with SpaceX aboard the orbital laboratory.

The crew members assigned to NASA’s SpaceX Crew-5 mission went into orbit following their launch to the International Space Station on Wednesday, October 5, from Launch Complex 39A at NASA’s Kennedy Space Center in Florida. The international crew will serve as the agency’s fifth commercial crew rotation mission with SpaceX aboard the orbital laboratory.