Hydrogen Liquefaction System Developed from Stirling Cryogenerators

Stirling cryogenerators have been widely used since the 1960s and 1970s for the production of LH2 at various institutes and research laboratories all over the world. In materials sciences, small-scale production was used to study the properties and behavior of LH2 and its effect on materials.

Stirling cryogenerators have been widely used since the 1960s and 1970s for the production of LH2 at various institutes and research laboratories all over the world. In materials sciences, small-scale production was used to study the properties and behavior of LH2 and its effect on materials.

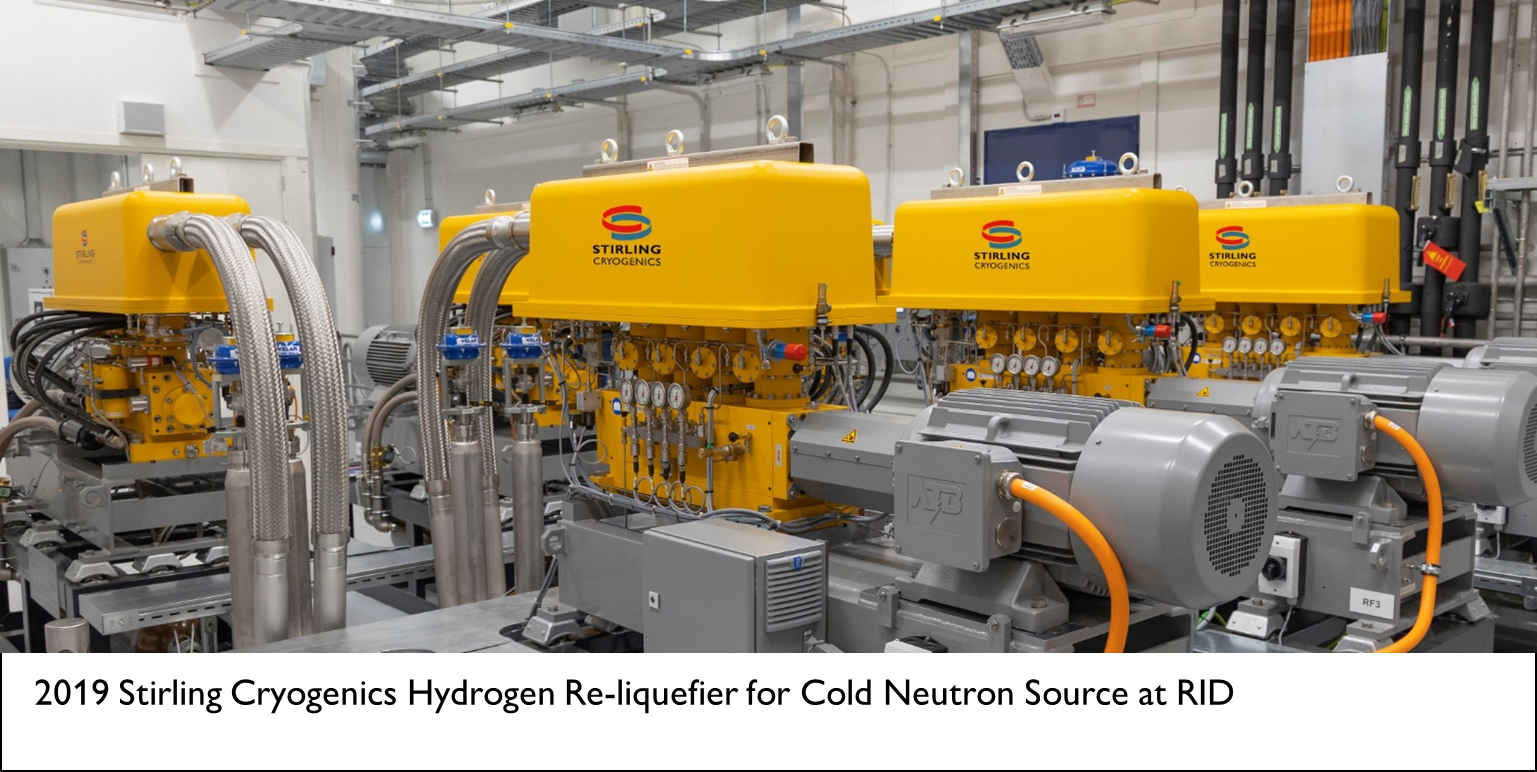

In scientific devices, Stirling cryo-generators have been used as LH2 reliquefiers to create cold neutron sources and to run H2/D2 distillation columns. Today, some of these vintage machines are still in use. For example, the one at the National Institute of Cryogenic and Isotope Separation in Romania was installed in 1973 and still operates today.

With the accelerated interest in a carbon-free society over the last few years, hydrogen and liquid hydrogen have come to the center of attention again. Many large, green H2 gas production facilities are being built or planned, and many for liquefaction purposes. Based on the same trusted two-stage Stirling cryogenerators used for more than 40 years, Stirling Cryogenics has designed a range of system sizes, from a small laboratory-scale unit producing 5 kg/day of LH2 and up to 400 kg/day containerized systems for industrial scale – all only needing H2 gas and electric power as input, producing converted para LH2 into a transfer vessel.

Hydrogen Liquefier Concept

The two-stage cryogenerator is available as a one-cylinder machine for liquefaction of 5 kg/day and as a four-cylinder machine for 30 kg/day of LH2. Incoming hydrogen gas is cooled to 80 K in the first stage and then liquefied at 20 K in the second stage. The liquid flows into a transfer vessel by gravity, from which the LH2 is transferred to the storage tank. A Stirling Cryogenics LH2 system will include all necessary internal piping, instrumentation, a transfer vessel and system control. All systems are built according to ATEX or other relevant coding. Optionally, catalytic ortho-para conversion, containerization and GH2 inlet gas purification can be offered. Stirling cryogenerators can also be supplied as modules to a system integrator, building the total system with the cryogenerators as the core.

For larger capacities, a number of cryogenerators are put in parallel. The design concept of the larger Stirling systems is that all cryogenerators will run independently of each other. Should one of the cryogenerators be offline, the liquefaction capacity of the other machines remains available. The second advantage is that the liquefaction capacity is easily adaptable to the momentary availability of H2. The number of operational cryogenerators can easily be adapted by just turning them on or off. Because a Stirling cryogenerator will start producing LH2 within 20 minutes of warm start-up, the system can react swiftly when GH2 flow increases again.

LH2 Boiloff Reliquefaction

Besides the production of LH2 from H2 gas production, the two-stage Stirling cryogenerator can also be used as a reliquefier for boiloff gas of a storage tank, preventing the blow-off of cold GH2. For such a setup, the cold GH2 is not fed to the cryogenerator, but the 20 K cooling power is transported into the storage tank.

Transport of the cooling power is done using Stirling’s CryoFans, creating a cold He gas loop connecting the 20 K heat exchanger of the cryogenerator with the reliquefaction heat exchanger built in the top side of the LH2 vessel. The evaporated GH2 will then remain inside the vessel.

Stirling Cryogenics is available to discuss the design set-up of a project-specific Stirling system for LH2 reliquefaction and BOG systems. www.stirlingcryogenics.eu

Image: 2019 Stirling Cryogenics hydrogen reliquefier for Cold Neutron Source at RID. Credit: Stirling Cryogenics